Monday, June 30, 2008

Sunday, June 29, 2008

"New" Solar Dish Could Transform Energy Production

(source: FOX NEWS) A new type of solar energy collector concentrates the sun into a beam that could melt steel. Researchers say the device could revolutionize global energy production.

(source: FOX NEWS) A new type of solar energy collector concentrates the sun into a beam that could melt steel. Researchers say the device could revolutionize global energy production.The prototype is a 12-foot-wide mirrored dish was made from a lightweight frame of thin, inexpensive aluminum tubing and strips of mirror. It concentrates sunlight by a factor of 1,000 to produce steam.

"This is actually the most efficient solar collector in existence," said Doug Wood, an inventor based in Washington state who patented key parts of the dish's design — the rights to which he has signed over to a team of students at MIT.

To test the prototype this week, MIT mechanical engineering Spencer Ahrens put a plank of wood in the beam and generated an almost instant puff of smoke. Video...

The thing does more than burn wood, of course. At the end of a 12-foot aluminum tube rising from the center of the dish is a black-painted coil of tubing that has water running through it. When the dish is pointing directly at the sun, the water in the coil flashes immediately into steam. Ahrens and his teammates have started a company, RawSolar, to hopefully mass produce the dishes. They could be set up in huge arrays to provide steam for industrial processing, or for heating or cooling buildings, as well as to hook up to steam turbines and generate electricity, according to an MIT statement.

Once in mass production***, such arrays should pay for themselves within two years or so with the energy they produce, the students figure. Wood, the inventor, said the students built the dish and improved on his design. "They really have simplified this and made it user-friendly, so anybody can build it," he said.

Wood said small dishes work best because it requires much less support structure and costs less for a given amount of collection area.

"I've looked for years at a variety of solar approaches, and this is the cheapest I've seen," said MIT Sloan School of Management lecturer David Pelly, in whose class the project first took shape last fall. "And the key thing in scaling it globally is that all of the materials are inexpensive and accessible anywhere in the world."

---------------------------------------------------------------------------

of course it "ain't" new; there were parabolic solar furnaces made in the late 1800's and one does not need MIT to figure this out... although, with "digital slide rulers" one can IMPROVE and PERFECT AND use newer, lighter weight materials and "micro" boilers, flash furnaces, trackers, etc. The bottom line is... the concept is still fairly BASIC.

***Why not share (make OPEN SOURCE or sell for $15 to $25 bucks) blueprints NOW! It ain't rocket science. ANYONE with basic mechanical experience CAN build one, anywhere, with junk* parts and aluminum foil. "To invent, you need a good imagination and a pile of junk." Thomas Edison

http://howtocat.blogspot.com/2008/06/solar-cooker-from-abandoned-satellite.html

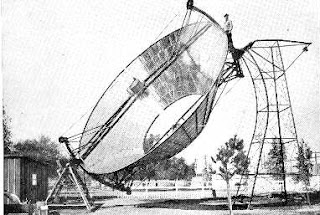

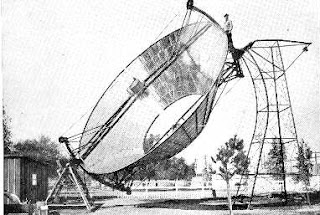

Image from 1897 "Solar Furnace" (see the "little guy" near the top?)

Image from 1897 "Solar Furnace" (see the "little guy" near the top?)solar power plants in the Mojave Desert

Wednesday, June 25, 2008

FIREWOOD I

"It's been said that a long straight row of firewood standing in the yard in springtime is like money in the bank. It is indeed. As it dries in the summer sunshine, you're collecting interest."

What is the best tree species for firewood? While there is always room for debate, we like to suggest that the best species in your area is the one that is most plentiful, easy to split and doesn't cover your hands and clothes with sticky sap.

What is the best tree species for firewood? While there is always room for debate, we like to suggest that the best species in your area is the one that is most plentiful, easy to split and doesn't cover your hands and clothes with sticky sap.

All wood, regardless of species, has about the same energy content per pound. The different species vary only in density. Traditionally, the favored trees in central North America were oak and maple because they are very dense and produce long-lasting coals. But these are valuable trees and in many areas are not plentiful enough to burn. No problem, just use softer woods like birch or poplar (aspen) or any other tree that is readily available. Keep in mind that people living in the coldest areas of North America have no hardwoods to burn and they get along just fine. Ultimately, it is more important to have wood that is cut and split to the right size and properly dried than it is to get the hardest wood available. http://www.woodheat.org

What is the best tree species for firewood? While there is always room for debate, we like to suggest that the best species in your area is the one that is most plentiful, easy to split and doesn't cover your hands and clothes with sticky sap.

What is the best tree species for firewood? While there is always room for debate, we like to suggest that the best species in your area is the one that is most plentiful, easy to split and doesn't cover your hands and clothes with sticky sap.All wood, regardless of species, has about the same energy content per pound. The different species vary only in density. Traditionally, the favored trees in central North America were oak and maple because they are very dense and produce long-lasting coals. But these are valuable trees and in many areas are not plentiful enough to burn. No problem, just use softer woods like birch or poplar (aspen) or any other tree that is readily available. Keep in mind that people living in the coldest areas of North America have no hardwoods to burn and they get along just fine. Ultimately, it is more important to have wood that is cut and split to the right size and properly dried than it is to get the hardest wood available. http://www.woodheat.org

"New" Solar Dish Could Transform Energy Production

(source: FOX NEWS) A new type of solar energy collector concentrates the sun into a beam that could melt steel. Researchers say the device could revolutionize global energy production.

(source: FOX NEWS) A new type of solar energy collector concentrates the sun into a beam that could melt steel. Researchers say the device could revolutionize global energy production.The prototype is a 12-foot-wide mirrored dish was made from a lightweight frame of thin, inexpensive aluminum tubing and strips of mirror. It concentrates sunlight by a factor of 1,000 to produce steam.

"This is actually the most efficient solar collector in existence," said Doug Wood, an inventor based in Washington state who patented key parts of the dish's design — the rights to which he has signed over to a team of students at MIT.

To test the prototype this week, MIT mechanical engineering Spencer Ahrens put a plank of wood in the beam and generated an almost instant puff of smoke. Video

The thing does more than burn wood, of course. At the end of a 12-foot aluminum tube rising from the center of the dish is a black-painted coil of tubing that has water running through it. When the dish is pointing directly at the sun, the water in the coil flashes immediately into steam. Ahrens and his teammates have started a company, RawSolar, to hopefully mass produce the dishes. They could be set up in huge arrays to provide steam for industrial processing, or for heating or cooling buildings, as well as to hook up to steam turbines and generate electricity, according to an MIT statement.

Once in mass production***, such arrays should pay for themselves within two years or so with the energy they produce, the students figure. Wood, the inventor, said the students built the dish and improved on his design. "They really have simplified this and made it user-friendly, so anybody can build it," he said.

Wood said small dishes work best because it requires much less support structure and costs less for a given amount of collection area.

"I've looked for years at a variety of solar approaches, and this is the cheapest I've seen," said MIT Sloan School of Management lecturer David Pelly, in whose class the project first took shape last fall. "And the key thing in scaling it globally is that all of the materials are inexpensive and accessible anywhere in the world."

-------------------

of course it "ain't" new; there were parabolic solar furnaces made in the late 1800's and one does not need MIT to figure this out... although, with "digital slide rulers" one can IMPROVE and PERFECT AND use newer, lighter weight materials and "micro" boilers, flash furnaces, trackers, etc. The bottom line is... the concept is still fairly BASIC.

***Why not share (make OPEN SOURCE or sell for $15 to $25 bucks) blueprints NOW! It ain't rocket science. ANYONE with basic mechanical experience CAN build one, anywhere, with junk* parts and aluminum foil. "To invent, you need a good imagination and a pile of junk." Thomas Edison

http://howtocat.blogspot.com/2008/06/solar-cooker-from-abandoned-satellite.html

Image from 1897 "Solar Furnace" (see the "little guy" near the top?)

Image from 1897 "Solar Furnace" (see the "little guy" near the top?)solar power plants in the Mojave Desert

Tuesday, June 24, 2008

Tuesday, June 17, 2008

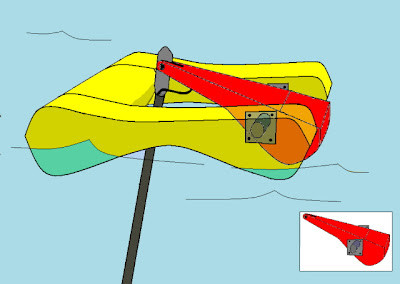

Energy from the Ocean/Very simple concept

http://www.swellfuel.com/

http://www.swellfuel.com/video... http://www.liveleak.com/view?i=845_1190218425

(pitiful videos and why do video people drown out a story with backGROUND muzak?)

It's the dudes, dames and entrepreneurs working from home, backyard or small business that come up with these kind of ideas and make them work for "cheap" out of junk or off-the-shelf parts. Mainstream school and college are 80% CRAP; a WASTE of MONEY (like corporate monopolies). Teach yourself, go to a Tech school, learn as you go (save the dough).

and Gore and the Globalist$ want $45 trillion for what?

and Gore and the Globalist$ want $45 trillion for what?

Subscribe to:

Posts (Atom)